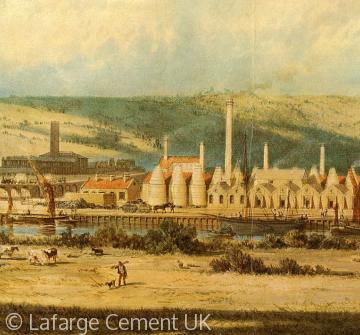

Brick and Cement making

Burham brick and cement works in 1885

Burham brick and cement works in 1885Before improvements in the transportation network in the 18th and 19th centuries, most lower status buildings were constructed using locally available materials. This lead to regional styles dictated by the availability of building materials, such as stone cottages in the Cotswolds and timber-framed cottages in Kent and Sussex. However the ability to transport bulk goods quickly and cheaply, combined with a growing population and the need for more houses led to the wider use of cheaper, mass-produced building materials.

Bricks made of sundried earth were used as a building material throughout the Ancient world, but it was the Romans who brought the technology of fired bricks to this country, with the Roman Legions operating mobile kilns and the bricks often bearing the mark of the Legion which supervised their production. Bricks were widely used in the buildings of Roman Britain and although some were reused in the building of medieval churches, local stone, timber and clunche (chalk) were the principal building materials until the 18th century.

Improvements in inland navigation and the growth of the canal network combined with the demand for cheap and quickly erected houses and construction materials for engineering works such as tunnels and viaducts lead to a dramatic expansion in the brick making industry. Clay was dug out by hand during the winter months by seasonal brick making gangs, turned into slurry to remove stones and poured into washbacks to settle for 6 to 9 months. When ready the clay would be dug out, shaped in wooden moulds and air dried before firing in clamp (later a tunnel kiln). Chalk was often added to the clay which gave the bricks a distinctive yellow colour. This bricks were widely used in London and the southeast and are known as ‘stock bricks’.

Cement, an independently setting binder was also used by the Romans who utilised its ability to set in wet conditions to construct baths and aqueducts. The development of modern cement also dates to the Industrial Revolution and the demand for building materials. The desire for a cheap building material which imitated good quality stone and for a reliable waterproof cement for lighthouses, harbours and tunnels, lead to experimentation by pioneers such as James Parker, William Aspdin and I.C. Johnson and the development of Roman and Portland cements at the end of the 18th century.

The key ingredients for making cement, chalk and clay were mixed to slurry and dried in large kilns to form a clinker (powder). The similarities in the materials required and manufacturing processes meant that brickworks and cement works were often located together, adjacent to large reserves of chalk.

The development of the continuous kiln in the 1890s allowed the production of cement on a massive scale and cement making remained an important industry in England until after the Second World War when the industry went into steady decline in the face of foreign competition.