Walton's Copperas House

Walton was one of the chief places for the production of Copperas or green vitriol (ferrous sulphate), which was used for a variety of purposes including inks and dyes. An important by-product of the manufacturing process was sulphuric acid. The Copperas was manufactured from pyrites (bisulphide of iron, FeS2) washed out of the London clay cliffs at Walton's Naze onto the shore. There the raw material was collected by "Copperas pickers" - the wives and children of fishermen and other poor people, who were paid in tokens. Some Copperas stones were also dregded up from the sea floor by boats. The material was then taken to a Copperas House (a factory) to be chemically transformed into the green vitriol.

Chronology at Walton:

It is not known exactly when Copperas production was established at Walton, but it was probably in the 17th century. Daniel Defoe, writing in 1724, noted that "At Walton-on-the-Naze, they find on the shoar copperas-stone in great quantities; and there are several works, call'd Copperas Houses where they make it with great expence". Samuel Dale, writing in 1730, stated that there had been two Copperas Houses in 1696, but that one had since been washed away by the sea. Coastal erosion was certainly a constant problem at Walton, although it also provided the raw pyritic material from the cliffs for the Copperas industry.

Copperas Houses were very valuable and most of those in south-east England were controlled by a group of families with strong social links. By 1702 the Walton works were in the hands of the Hopkins family who owned other works including that at Brightlingsea. Rights to the raw Copperas found on the shore were usually owned by the local Lord of the Manor from whom the Copperas manufacturers took a lease to enable them to legally collect it. In 1772 the Lord of the Manor of Walton, the Rt. Hon. William Henry, Earl of Rochford, of St Osyth Priory, leased the rights to Ephraim Rinhold Seelil (or Seckl) for 21 years at £42 p.a. Seelil owned a similar works at Blackwall (Kent). By the early 19th century the Walton factory had passed to Charles Pearson, a Copperas magnate who attempted to dominate the industry and who controlled 30% of production in southern England by 1808. The attempt failed and the Pearson family were bankrupted c.1835 as the industry began to decline. Although production at Walton ceased sometime in the earlier 19th century, the raw material continued to be collected there until the late 19th century when it was being transported to chemical factories in London and Ipswich.

The Copperas House and the manufacturing process:

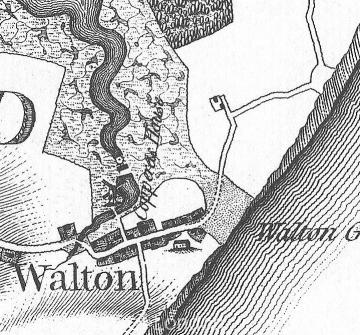

There is a detailed inventory of the Copperas House from 1702 indicating that it had a boiler and several coolers, a great variety of tools and equipment and much old scrap iron. The Copperas House was located between Mill Lane and Vicarage Lane, close to Walton Channel, the Tidal Mill and wharves there, a water supply being important for both the manufacturing process and for the export of the final product. The factory needed quite a lot of open space, typically called a Copperas Ground, where the large tanks could be arranged. A set of depositions in a legal case, probably from the later 18th century, records a dispute over the ownership and rights of access to Copperas House Wharf. In 1907 there was still a piece of open ground at Walton saturated with sulphurous matter and having visible remnants of leaden tanks and pipes from the old factory.

An account of the manufacture of Copperas at Walton in the 19th century, recorded in VCH Essex, Volume II, notes the process used. The Copperas was first packed into heaps into which scrap-iron was introduced and then moistened. The action of the air and water then oxidised the copperas into ferrous sulphate of iron (green vitriol or Copperas) and sulphuric acid. Extra scrap iron could be added which reacted with the sulphuric acid to produce more vitriol. The solution was then removed to leaden tanks or boilers and the water evaoprated by heat so concentrating the product. It was then removed again to a cooler, where rods were placed across the product onto which the Copperas crystallized. It could then be gathered and packed into barrels.

For more details of the origins and development of the whole industry see the separate word document provided as an Explore Asset "The Copperas Industry".

Sources:

Essex Record Office, D/DB T608; D/DHw T19; D/Y 37/2/43; D/DU 5/49, 5/50, 5/62.

J. Chapman and P. Andre, Map of Essex (1777).

S. Dale, The History and Antiquities of Harwich and Dovercourt (1730)

W. George and S. Vincent, 'Report of Field Meeting to walton-on-the-Naze and Wrabness', Tertiary Research, Vol. 1, No. 3 (June 1777), pp.87-90.

J.C. Shenstone, 'Copperas Industry', in W. Page and J.H. Round (eds), The Victoria Hitsory of the County of Essex, Vol. II (1907), pp. 411-13.

T. Allen, M. Cotterill & G. Pike, Copperas. An Account of the Whitstable Works and the first Industrial-scale chemical production in England (Canterbury Archeological Trust, Occasional Paper, No. 2, 2004).

Content derived from research undertaken as part of the Victoria County History project