Horsehair Industry of Castle Cary

The success of the horsehair industry in Castle Cary was at least partly due to the availability of the hair as many horses were bred in the area in the mid 19th century for agriculture and transport.[1] The availability of labour familiar with textile work, underemployed with the decline of the stocking industry and a plentiful supply of water from the river and springs for water and later steam power, encouraged the development of horsehair factories in the 19th century.

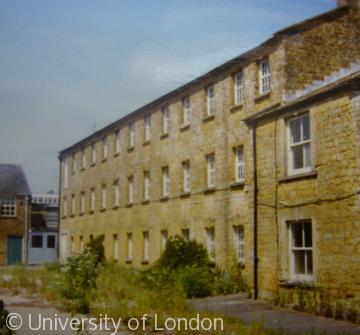

Thomas Matthews, a girthwebb manufacturer, also employed people weaving horsehair at home and in 1828 acquired the former silk house at Florida for the manufacture of twine, girthwebb, and hair seating and rebuilt it. There were 26 people weaving hair in 1831.[2] Matthews and his son, flax spinners and horsehair weavers, continued to produce hair seating until 1861 when Thomas Matthews was 73.[3]

John Boyd is said to have started his horsehair business in a cottage in the Congregational chapel yard in 1837[4] although only in his early 20s, the son of a merchant at Cumnock, Ayrshire who came to England as a travelling draper. By 1840 24 women and children and 2 men were weaving haircloth and in 1841 there were about 30 hair weavers of both sexes and three starchers, two black starchers, and a dyer, probably employed by Matthews and Boyd.[5] In 1851 Boyd, who also continued his drapery business, employed 34 children, 30 women, and 9 men, probably in their own homes[6] and the same year built his new factory, often known as the Ansford factory, behind Ochiltree House,[7] in what is now Upper High Street.[8] In 1871 153 horsehair workers were recorded although Boyd claimed to employ 190, mostly children.[9] By this date he had taken over the Quaperlake silk mill in Bruton for preparing horsehair for seating weaving.[10] In 1877 Boyd’s installed 50 power looms, invented in 1872 by William Henderson,[11] in a new brick factory with glass roofs to the north of the 1851 buildings,[12] but c. 200 handlooms were still widely used in the early 20th century, some possibly in workers’ homes.[13] In 1901 there were c. 130 horsehair workers in Castle Cary and Ansford, mostly employed by Boyd’s but some by White’sThe horse tail hair, then from Siberia and China, was washed and disinfected, sorted into colours and lengths, soaked, combed, and dyed before being woven on a black linen warp to produce the lustrous sateen fabric which was the firm’s main product. Large numbers of little girls were formerly employed picking and sorting because it was delicate work but following the restrictions on child labour more machinery was installed including a mechanical picker. Hair was also woven on handlooms into tailors’ padding cloth known as crinoline, traditionally with a white or lavender cotton warp. Hair was also used for toothbrushes, hair brushes, wigs, sieves, fishing lines, military plumes, and some musical instruments. Large quantities were curled for stuffing sometimes mixed with cow and hog hairs, which were also used to produce course cloths such as those used in cider making. The ability of horsehair to maintain its shape in heat led to its widespread use for blinds especially on trains.[14]

In 1956 Boyd’s left the Ansford factory and rented a two-storey building at Higher Flax mills taking 45 of their 150 looms. The company amalgamated with Donne’s c.1977 as T S Donne and John Boyd and Co. Ltd. and bought fourteen early 20th-century American looms which made lightweight cloth with dry hair.[15] Since 1984 the business has been run by John Boyd Textiles Limited using 30 of the original 1870s looms,[16] although powered by electric motors. In 2001 it was the only business of its kind in Britain and the only horsehair factory in Europe using powered looms.

In 1870 James White, who had been foreman at Boyd’s, opened a hair-seating factory at the Bailey Hill premises formerly used by Donnes and before them by Thomas Matthews. By 1881 James and his son John employed 39 hands.[17] After 1883 Whites rebuilt the factory and expanded the site by acquiring and demolishing cottages.[40] By 1896 they had two factories at Bailey Hill and a new warehouse.[41] They remained in business until 1926 manufacturing sateen hair seating and brush makers’ drafts.[42]

[1] TNA, HO 107/937; ibid. RG 9/1646; RG 10/2421; RG 12/1901; PO Dir. Som. (1861—75); Morris & Co. Dir. Som. (1872); Kelly’s Dir. Som. (1883, 1899). More information will be found in the forthcoming VCH Somerset X, Castle Cary. Also see information on the VCH Somerset website: www.victoriacountyhistory/Counties/Somerset.

[2] VCH Som. II, 425; SRO, tithe award; Robson’s Dir. Som. (1839); Castle Cary Visitor May, June 1900.

[3] TNA, HO 107/1931; ibid. RG 9/1646.

[4] SRO, tithe award (gives name as Henry Boyd); McGarvie, Castle Cary, 9; date on entrance to Boyd’s factory behind Ochiltree House.

[5] VCH Som. II, 418; TNA, HO 107/937.

[6] TNA, HO 107/1931.

[7 Said to be named after John Boyd’s birthplace in Scotland but he is also said to have been born at Cumnock, both parishes in Ayrshire.

[8] McGarvie, Castle Cary, plate 1.

[9] TNA, RG 10/2422

[10] Castle Cary Visitor May 1906; VCH Som. VII, 33.

[11] His invention was challenged by the holders of an American patent from whom Boyd’s had to buy a licence: English Heritage, John Boyd’s horsehair factory (2000), 14.

[12] McGarvie, Castle Cary, plate 3.

[13] VCH Som. II 425; Castle Cary Visitor April 1905; April 1912; EH, John Boyd’s, 14.

[14] SRO, PAM 813; Castle Cary Visitor Sep. 1906; inf. from John Boyd Textiles.

[15] McGarvie, Castle Cary, 42—3; EH, John Boyd’s, app. III.

[16] Others and parts are stored on site.

[17] A. W. Grafton, Notes on Castle Cary (c. 1890), 21—2; Hants. RO 30M73/F7; TNA, RG 11/2395.

[18] SRO, D/P/cas 4/3/1; Castle Cary Visitor May 1900.

[19] SRO, D/R/winc 14/2/13.

[20] TNA, RG 12/1901; Kelly’s Dir. Som. (1894—1931); VCH Som. II, 425.

We are sorry that some images have been removed from the site. This was done at the request of Boyd's who were worried about industrial espionage.

Content generated during research for Victoria County History Somerset Volume X. More information is available on the VCH Somerset website